Technology

Award Winning Technology and Services

The customer awards we have received demonstrate our customers’ satisfaction with our high quality and stable delivery supported by our technology.

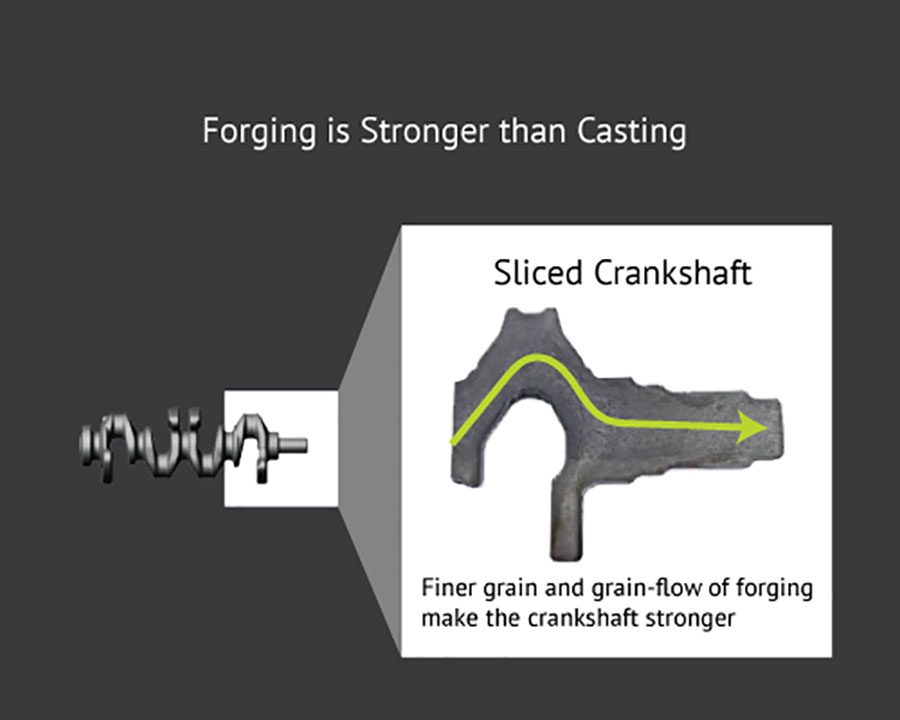

Technology Shift from Casting to Forging

Forging is Stronger than Casting

The University of Toledo Industrial & Manufacturing Engineering Department published an excellent research paper on forging vs casting crankshafts, proving the following results:

- Forged parts had a 26% higher tensile strength than the cast parts. This means you can have stronger crankshafts at a lower part weight.

- Forged parts have a 37% higher fatigue strength resulting in a factor of six longer fatigue life. This means that a forged crankshaft is going to last longer.

- Cast iron only has 66% of the yield strength of forged steel. Yield strength is an indicator of what load a crankshaft will hold before starting to deform.

- The forged parts had a 58% reduction in area when pulled to failure. The cast parts only had a 6% reduction in area. That means there would be much greater deformation before failure in a forged part.

The title of the research paper is “Fatigue Performance Comparison and Life Predictions of Forged Steel & Ductile Cast Iron Crankshafts” written by Jonathan Williams, Farzin Montazersadgh, and Ali Fatemi, Graduate Assistants and Professor, respectively, Mechanical, Industrial & Manufacturing Engineering Department, The University Of Toledo – Toledo, Ohio.

Forging Innovation

Our state-of-the-art high speed forging line can forge crankshafts every 9 seconds with fully automated operation.

Forging Innovation

Line 4: 5000T High Speed Press (2015 Sumitomo Heavy Industries)

Third Party Certifications

Click on the PDF to view certifications.

Customer Certifications

View certifications below.

- General Motors BIQS